Quietspray is one of the world’s leading seamless acoustic ceiling providers and installers with approved and successful projects worldwide. We manufacture our very own acoustic panel in Cheshire, England. Our acoustic panel is made from 94% recycled glass with a beautiful marble granular acoustic plaster finish.

For installing our Quietspray system the conditions of the environment must be the following.

Quietspray installers have to have access to the ceiling areas without other construction workers blocking the areas of install.

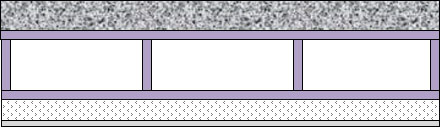

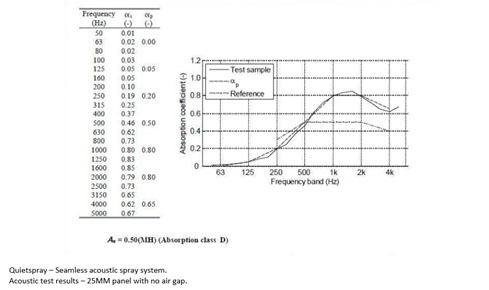

Class D Quietspray 30

Concrete soffit, 2mm Quietstone adhesive, 25mm Quietstone Light board, 3mm acoustic plaster

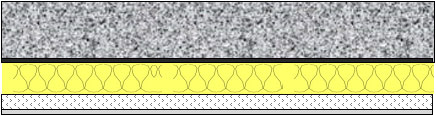

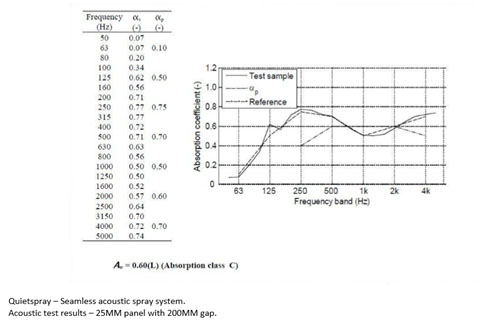

Class C Quietspray 228

Concrete Soffit, 200mm suspended frame system with 300mm centres. The frame system creates a 200mm air gap, 25mm Quietstone Light board, 40mm screws required to hold Quietstone Light board to the frame system, 3mm acoustic plaster

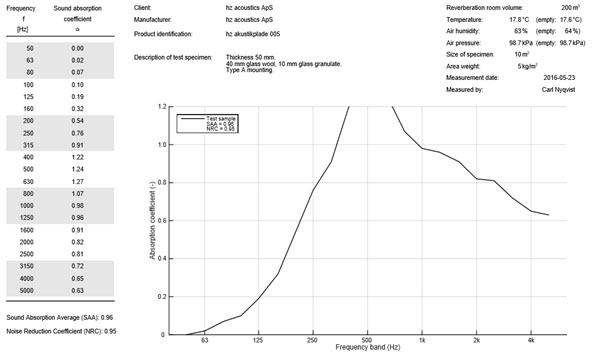

Class A Quietspray 55

Concrete soffit, 2mm Quietstone adhesive, 40mm Quietstone high density mineral wool, 10mm Quietstone Light board, 3mm acoustic plaster.

Class D Quietspray 30mm thick system

Class C Quietspray 228mm thick system

Class A Quietspray 55mm thick system

Our installation times are based on three to four men working on a 40-60m2 ceiling project.

Day 1 and 2: bonding the Quietstone Light boards to ceiling

Day 3, Applying Quietstone filler to the joints and sanding the surface

Day 4 and 5 Applying acoustic plaster to the surface of the ceiling

Day 6 and 7 – Drying times

The perfect conditions for our acoustic plaster to dry are 15 degrees + and airflow

Cleaning and maintenance guide.

To ensure continual high performance of our acoustic seamless ceiling system the following regime should be followed.

For further inquiries and prices please contact us by one of the following methods:

Tel: 01625 576970

Email: info@quietstone.co.uk

Address: Quietstone UK Ltd, Nab Quarry, Pott Shrigley, Cheshire, SK10 5SD

Nab Quarry, Pott Shrigley, Macclesfield, Cheshire, SK10 5SD